News & Views

SI Solutions' annual technical magazine highlighting asset management technology and application insights across the industries we serve Download Volume 55In This Issue:

2. CEO Introduction

4. Replacement of Large Equipment in Nuclear Power Plants

9. Cathodic Protection Implementation for SLR: An Iterative Process

17. Joint Industry Project: APTITUDE Flaw Evaluation Software

20. Delivering Just-in-Time Winterization Upgrades to Meet ERCOT Requirements

24. Nuclear Plant Resin Optimization

28. Digital Twins – Concept, Uses, and Adoption in Industry

34. Pre-Planning for Investigations of Catastrophic Events

37. Steam Turbine Failure Cause Evaluation

45. Life Extension of Raw Water Piping Through Life Cycle Management Practices

48. Nonintrusive and Robotic Solutions for Tank Asset Management

52. Materials Lab Featured Damage Mechanism – Creep Fatigue in Steam-Cooled Boiler and HRSG Tubes

54. UPDATE: Encoded Phased Array Ultrasonic Examination Services for CASS Piping Welds

61. Managing High Energy Piping: The Fundamental Approach, Integrating NDE and Engineering (Part-1)

News & Views, Volume 55 Article Summaries

CEO Introduction

SI Solutions CEO Mark W. Marano shares his thoughts on the next evolution of our organization following an exciting change of ownership. Mr. Marano also comments on the wide variety of cutting-edge work we are doing, as demonstrated in several key articles in this issue, the first of which features our Process Industries group (C2C Technical Services) and our Controls Engineering team at SC Solutions.

Replacement of Large Equipment in Nuclear Power Plants

With many U.S. nuclear plants having extended operation well beyond their original licensed life, it is necessary to replace certain critical process components (e.g., large pumps, turbine rotors, heat exchangers). In many cases, equipment manufacturers are asked to provide larger, heavier equipment to deliver higher output and improve efficiency. Prior to installation, the existing structure must be evaluated for the larger static loads as well as one-time loads applied during movement (transit and rigging). SI has successfully collaborated with owners, design engineers, equipment manufacturers, and installation contractors to ensure safety and minimize disruption during this process.

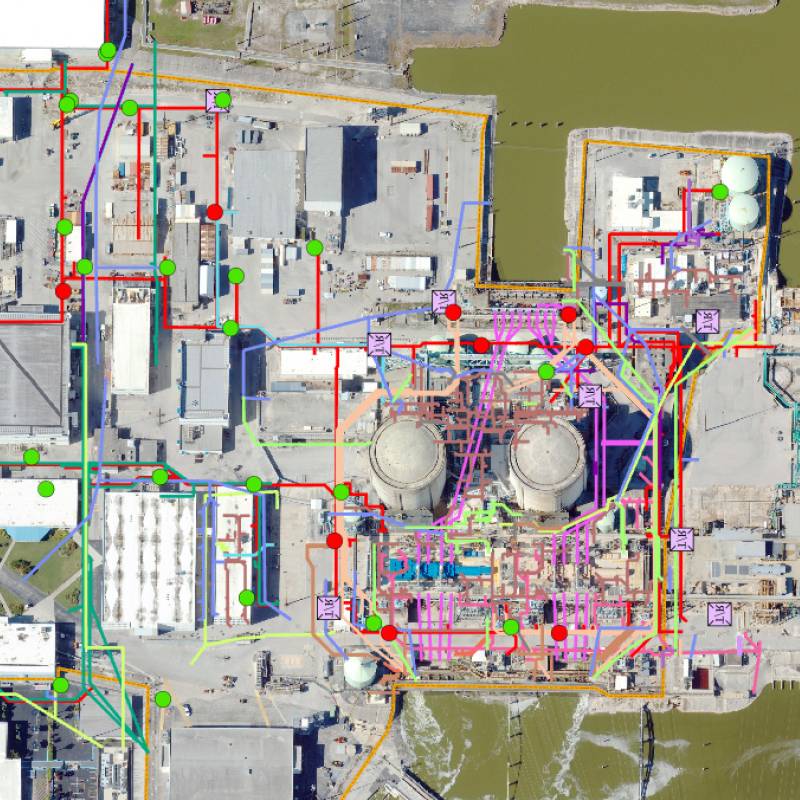

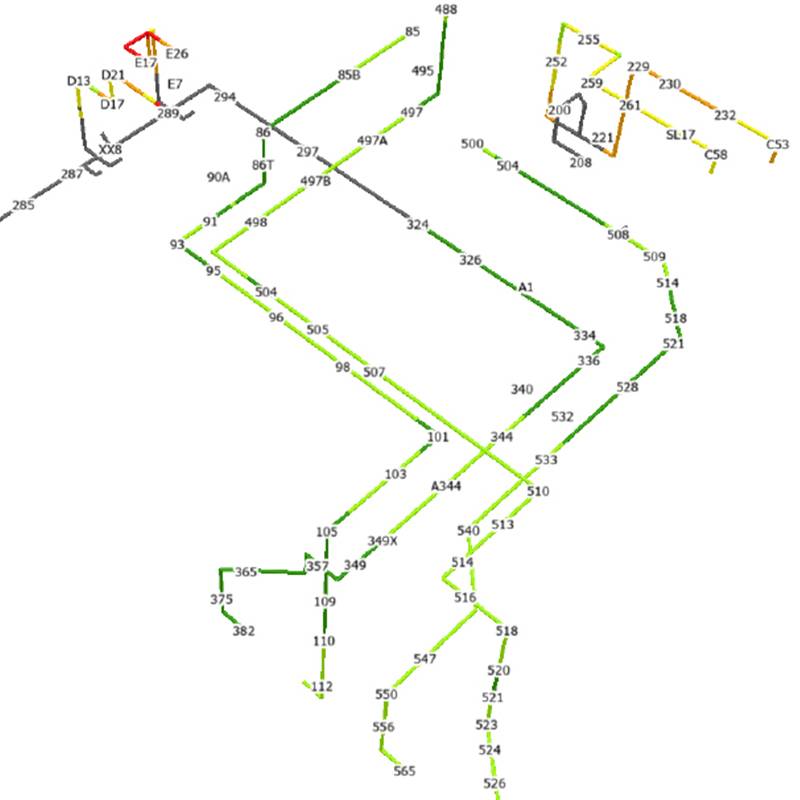

Cathodic Protection Implementation for SLR: An Iterative Process

SI was engaged to design, install, and commission a site-wide impressed current cathodic protection (ICCP) system for the Turkey Point Nuclear Generating Station (PTN) to meet the site’s ongoing subsequent license renewal (SLR) commitments. Prior to its SLR application, PTN did not have a CP system for buried piping; designing and installing an all-new ICCP system at this legacy facility posed unique challenges and required more support than a typical CP refurbishment project. This article summarizes the site-specific requirements, challenges and adjustments made by SI as part of our project methodology, which resulted in the first large-scale CP implementation for a nuclear site pursuing SLR.

Joint Industry Project: APTITUDE Flaw Evaluation Software

Aging pipeline infrastructure and past incidents have driven PHMSA to introduce stricter regulations, requiring operators to conduct rigorous evaluation of flaws identified during inspections. Recognizing these needs, SI developed APTITUDE, an analytical tool for calculating Predicted Failure Pressure (PFP) and determining reassessment intervals per 49 CFR §192.712, §192.933, and §192.714. In 2024, SI convened a joint industry project (JIP) with seven participating operators, upgrading APTITUDE to a web-based platform with enhanced capabilities and accessibility that is available as of March 2025. Later this year, additional features will be introduced, providing further benefits to subscribed operators.

Delivering Just-in-Time Winterization Upgrades to Meet ERCOT Requirements

This article details a significant winterization effort conducted by C2C Technical Services, an SI Solutions company, on behalf of a large petrochemical facility in Texas. The project, driven by ERCOT requirements imposed in the wake of a significant 2021 storm, involved a gap analysis to identify critical instruments, detailed engineering to select appropriate mitigation measures, and just-in-time field implementation on an accelerated timetable. These measures were proven effective when the facility operated without any adverse effects during a similar storm in January 2025.

Nuclear Plant Resin Optimization

In a nuclear power plant, the quality of water used in the primary and secondary processes is critical for safe and efficient operation. Resin selection plays a key role in maintaining water quality by removing ionic impurities and radioactive contaminants from cooling and wastewater systems to support corrosion control and minimizing radiation fields while balancing O&M costs. Over time, resins become exhausted and must be replaced or regenerated, leading to waste generation, increased costs, and potential operational inefficiencies. SI’s OSS team specializes in resin optimization programs designed to maximize resin lifespan, improve water chemistry and filtration performance, as well as reduce waste. This article details SI’s industry-leading approach to resin optimization, with several case studies illustrating the measurable impact of these projects.

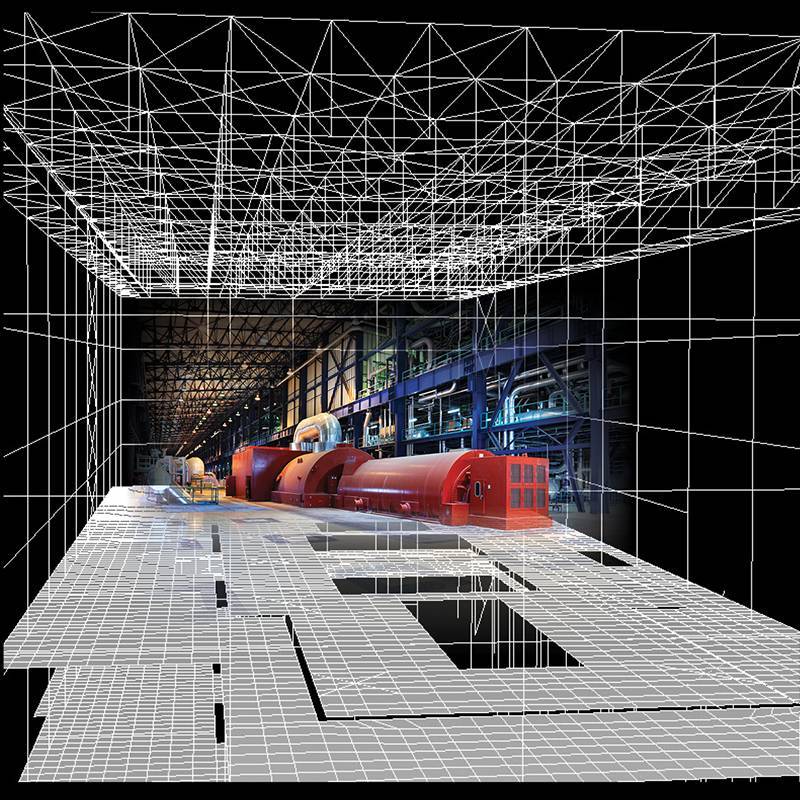

Digital Twins – Concept, Uses, and Adoption in Industry

Digital Twins are dynamically synchronized digital representations of physical equipment or systems. This technology is emerging in the power generation industry and assists with early detection of potential failures, failure accommodation, optimized maintenance schedules, development of next-generation equipment, and workforce training.

Pre-Planning for Investigations of Catastrophic Events

In the event of a major failure, facilities that have pre-planned for the early stages of the investigation process have the best chance of learning the cause(s) of the event and are, therefore, more capable of implementing appropriate changes to prevent repeat events. Structural Integrity Associates (SI) can assist with pre-planning needs, and can also assist with incident investigations and failure analyses of components of interest.

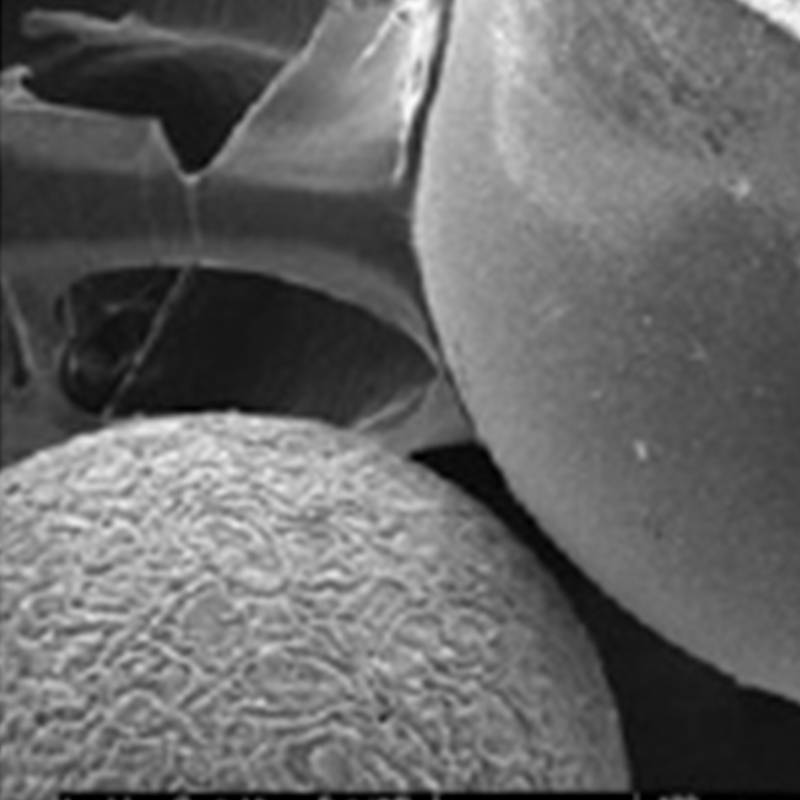

Steam Turbine Failure Evaluation

This article summarizes SI’s independent root cause analysis of a catastrophic steam turbine failure at a coal-fired power plant. The investigation identified that creep-driven rotor material liberation in the intermediate pressure (IP) turbine was the initiating cause of the event, which led to severe damage throughout other portions of the turbine-generator train. SI provided metallurgical evaluation, detailed finite element analysis, review of operating data, and customized extent-of-condition inspection plans to assess fleet-wide risk and prevent subsequent failures.

Life Extension of Raw Water Piping Through Life Cycles Management Practices

SI has pioneered a Life Cycle Management (LCM) approach that significantly improves asset management of raw water piping, which favors planning and evaluations before inspections are performed. SI’s MAPPro 4.0 Above Ground Piping software provides the framework for LCM assessments and managing risk for raw and service water piping assets.

Nonintrusive and Robotic Solutions for Tank Asset Management

Nuclear plant aging management programs require periodic inspections of liquid storage tanks. Traditional inspection methods can be disruptive, requiring tanks to be drained to provide personnel access. SI has developed innovative solutions, including screening techniques that can identify degradation from the tank exterior, and submersible robotics that perform comprehensive NDE without draining. Although initially developed for nuclear applications, these technologies can be employed at conventional power generation, petrochemical, and municipal utility facilities

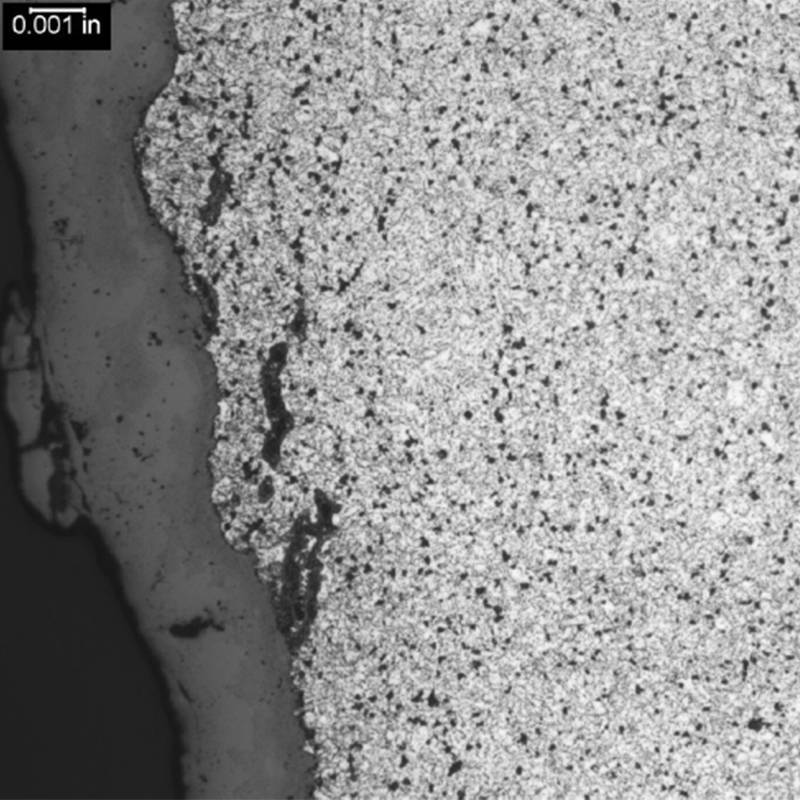

Materials Lab Featured Damage Mechanism: Creep Fatigue in Steam-Cooled Boiler and HRSG Tubes

Creep-fatigue is caused by the accumulation of damage through synergistic interaction of cyclic stress and an elevated operating temperature. The creep and fatigue components of the damage usually occur at different periods in the thermal cycle to result in a failure with characteristics of both mechanisms. Structural Integrity has an experienced group of materials specialists and a full-service metallurgical testing laboratory that can help with any situation involving material property characterization.

UPDATE: Encoded Phased Array Ultrasonic Examination Services for Cast Austenitic Stainless Steel (CASS) Piping Welds in Pressurized Water Reactor (PWR) Coolant Systems

The CASS piping in many nuclear plants present challenges for effective ultrasonic examinations. As a result, most CASS piping welds have not been subjected to a meaningful and effective volumetric examination since radiography was performed during plant construction. SI has developed and demonstrated a Code-compliant, procedure that enables in-service volumetric UT inspection in full compliance with the NRC’s 10CFR50.55a.

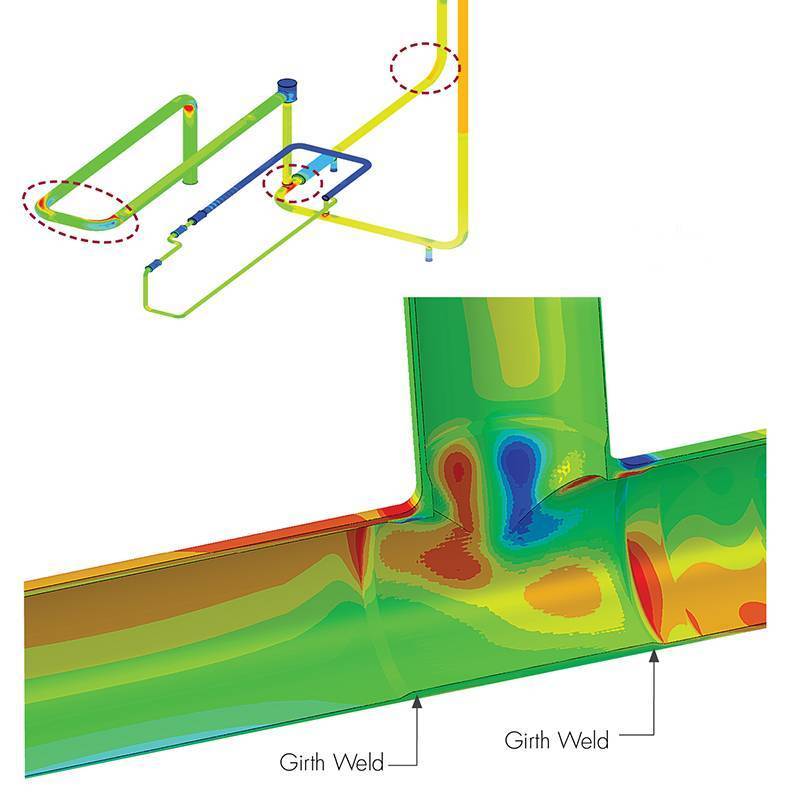

Managing High Energy Piping: The Fundamental Approach, Integrating NDE and Engineering (Part-1)

HEP programs ensure safe and reliable operation of high-energy piping at power and process facilities by identifying and inspecting critical locations and evaluating fitness for service. Seamless integration between NDE and engineering helps optimize inspections, minimize surprises, and accelerate serviceability evaluations. This maximizes value for owners/operators, enabling confident asset management and avoiding unnecessary downtime.